Monitoring and Planning for Rehabilitating Aging Infrastructure in Houston

Authors: Benjamin McCray PE and Joseph Wager EIT

Hundreds of miles of large diameter water transmission lines are buried underground in the greater Houston area. A few of these critical lines and even fewer have suffered previous catastrophic failures, disrupted services to key areas of the city yet remain in service today. This has been made possible through the City’s flexibility with contracting bid packages and developing new transmission line projects that include rehabilitation to adjacent or other impacted lines at the same time. An example of this is the project known as “SWTP 72-inch Water Line from Emancipation to Tuam.” Recently, the City of Houston Public Works Department and Lockwood, Andrews & Newnam, Inc., (LAN) won the Texas American Public Works Association (APWA) Project of the Year Award for Environment for this endeavor. Over 48 million dollars were budgeted for the project and infrastructure being installed. Around 1.5 million was dedicated to rehabilitating a key 60-inch water line instrumental in providing water to areas in and around the downtown area. These funds are key in continuing to monitor and maintain this older line, and as Panduranga Kuruva, managing engineer with the City of Houston’s Capital Projects discusses, “It is an extensive task of rehabilitating transmission mains, especially prestressed concrete cylinder pipe (PCCP) lines. It involves a complicated balance of identifying the defects and methods of repair, the best time to shut down the line, the availability of specialty contractors to do the work, funding and planning the repairs while safeguarding the water supply with consistent pressures to deliver to the Houston community.”

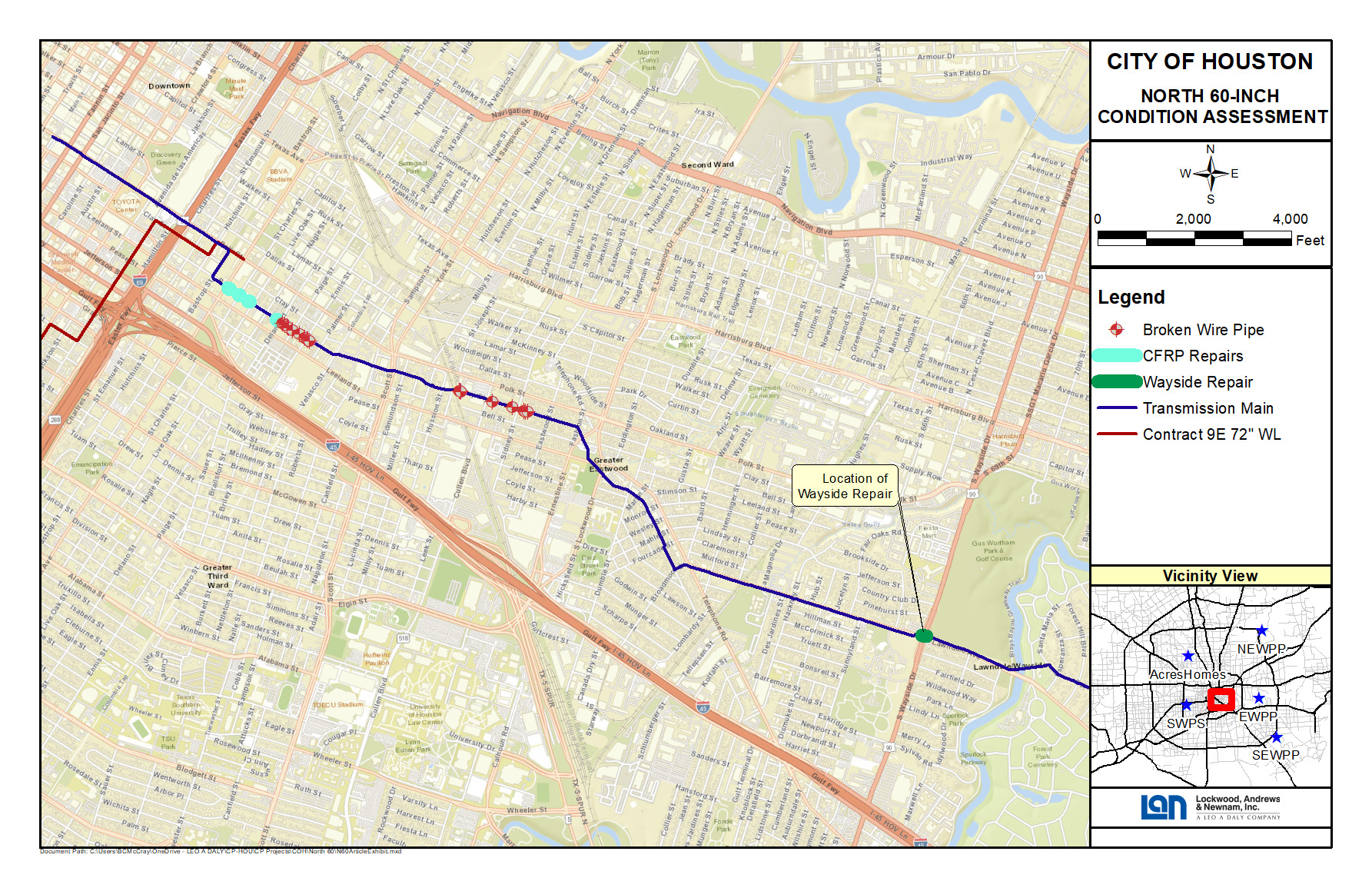

Years ago, this work was planned, and a concept was developed for designing and installing an additional water transmission line from east of downtown Houston to a key repump station near the Houston Galleria area. This project was years in development and included a much-needed interconnection to the “North 60” water transmission line near the project start. The interconnection required a full shutdown of the water line to facilitate the work, which is a complicated process for such a critical aged line. The City operates near capacity during peak demand seasons and can only put transmission line segments out of service for short time periods. Critical lines like the North 60, a prestressed concrete cylinder pipe (PCCP), are typically only shut down for a short duration at opportune times and are quickly returned to service.

Late in 2002, the North 60 suffered a catastrophic failure; emergency repairs were made, including the replacement of an additional distressed pipe near the failure location. Then the line was put back in service. Quickly after restoring the line to service, the City began planning an additional shutdown of the line for an extensive assessment and rehabilitation project. Around 10 years later, a planned shutdown was made with an acoustic fiber optic (AFO) monitoring system installed and a longer length of electromagnetic (EMT) inspection performed. EMT is performed by a specialty contractor through a manned or robotic entry into the water line. PCCP is a composite pipe made of concrete and steel in which a high-strength wire is wrapped around a steel cylinder, while under tension, to compress the steel cylinder and provide additional strength to the pipe. The electromagnetic equipment is used to induce current onto the prestressing wire and measure any loss of continuity on the prestressing wire resulting in a quantity of prestressing wire wrap breaking in the pipe. When EMT is coupled with an AFO system a municipality can effectively “listen” to the pipeline and record acoustic anomalies or sound events that impact the acoustic fiberoptics’ light. These anomalies are analyzed and can indicate when a break in the prestressing wire, or an external event that had sound waves large enough to impact the AFO within the pipeline. Systems like these are frequently used by entities to monitor the structure of a PCCP pipeline and prioritize repairs on distressed segments with the greatest risk of failure by quantifying a number of broken wire wraps with an EMT survey and then monitoring future breaks with the AFO system. By placing the North 60 pipeline under a monitoring system, the City is able to react as damage is monitored and prevent additional failures.

After installation of the AFO and additional electromagnetic inspections, the City now had an estimated condition for a much larger portion of the pipeline. This condition assessment indicated that numerous other pipe segments were distressed to varying levels, leaving lower levels of strength than originally installed and a pipeline in need of future repairs. Over the years, the City has continued to maintain this AFO monitoring system and recorded additional wire breaks on a yearly basis. As the City has continued to grow, additional water lines continued to be needed with the City making efforts to plan and install them in areas to increase redundancy to critical lines and make the water system less susceptible to single events that impact a metropolis as large as Houston. This is where the 72-inch water line that had recently been completed comes into play.

As potential alternative routes were evaluated, system engineers found an additional water transmission line from east of downtown to the west side of the inner loop would provide much-needed redundancy to a second 66-inch PCCP line with known distress and which is critical to operations of a repump station for the western portions of the city. A years-long planning and design process began with several alignments considered. In this work, an interconnection to the North 60 was identified as beneficial. With a shutdown for the interconnection occurring, the City would be able to rehabilitate distressed segments, perform new electromagnetic surveys, and maintain the service level of the North 60 much closer to initial levels of structural integrity. After years of planning, a final design for the new 72-inch water line was advertised. Various contracting firms bid for the project which included scope for the interconnection, condition assessment, and rehabilitation of previously identified distressed segments of the North 60.

Construction packages like this typically include years of construction for the new infrastructure alone. Planning the shutdown of existing transmission lines within the City of Houston adds an additional complexity to this construction and requires the City to have windows of potential shutdowns for additional work. Drinking Water Operations (DWO) and City crews must maintain service to customers within acceptable pressure levels through the existing system limiting the number of large-diameter transmission lines that can be shut down at a time. When a key lines like the North 60 is shut down, no other major waterlines serving the same part of town can afford to be shut down. The construction package included contingency items for delaying the interconnection to the next low-demand period and flexible items to cover the rehabilitation. The initial shutdown window had to be pushed to the next low-demand period and was almost pushed back a second time. In performing work for transmission lines like this, the coordination for operations is crucial and time consuming.

That is why it was considered a critical issue when the monitoring system on the North 60 identified additional wire breaks in several pipes bringing them potential risk of failure. It all started a few months prior to the planned shutdown of the North 60, when additional wire breaks placed a segment of pipe into a higher risk of failure category triggering the need for rehabilitation to be planned. Before long, the preferred choice was clear: the planned shutdown needed to be extended thousands of feet to include dewatering and repairs on the portion being monitored. This is where LAN and City staff worked together to modify the contract to keep a satisfactory level of service on the aging line. Modifications to the initial construction contract and additional coordination were not the only actions needed to make this repair happen. Several other construction packages and additional improvements were also made during the years of planning resulting in the City being able to prevent larger shutdowns and impacts to customers to address the distressed pipe segments.

LAN has worked for decades as the City of Houston’s Surface Water Transmission Program (SWTP) Manager. Currently, numerous large-diameter water lines and work have been completed to increase the City’s use of surface water and decrease the use of groundwater. This $660 million program has delivered more than 300 miles of transmission and distribution lines of up to 108-inches in diameter. In addition to these new water lines, LAN has assisted with improvements and rehabilitation of numerous transmission lines. The North 60 has been one of the most storied lines out of them all, with numerous breaks, leaks, and repairs documented over the SWTP’s duration. The projects LAN has performed for the City have included emergency repairs, condition assessment, maintenance, installation of new line valve, replacement of interconnects, and installation of the acoustic monitoring system.

Starting around 2010 this included a series of miscellaneous contracts around the City that included Diameter Valve Replacement Contract Number 1. This contract was the first of several planned, where numerous key isolation valves were identified within the City’s system for repairs. In this particular contract, two 60-inch butterfly valves were identified as key items for maintaining the service level of the North 60 and assisting with future shutdowns. By having this large diameter valve contract, the City located, operated, and tested numerous 60-inch water line valves along the pipeline to test their ability to fully operate and hold water. With one of the valves in need of repair needing a shutdown and striving to create a minimal impact on the system, temporary line-stops were included to minimize the effects of these shutdowns. These actions provided the City with additional new valves in good condition and allowed the city to confirm some valves previously unknown could be used. Installation of the linestops provided a location where temporary line stops could be reinstalled if needed. Temporary line stops require the pipeline to be tapped with an adequately sized outlet with a temporary valve that can hold water. While the City coordinated work throughout their system, installed new water lines, made connections to the system, and made larger repairs through the miscellaneous contracts, they prepared for the 72-inch water line project’s planned interconnection by placing new valves at critical locations to facilitate the assessment. All the valve work performed provided essential information critical for the planning of the additional repair. A recent history of valve operations and an understanding of which valves fail to hold water can allow the team to plan the work while minimizing disruption.

Armed with the recent valve history and shutdown experiences, the City and LAN began discussing options for adding the repair at Lawndale. Several options were evaluated simultaneously. First, the modification of the 72-inch water line contract and planned rehabilitation work to shift the planned internal repairs to the new location were addressed. Second, the City and LAN discussed the possibility of issuing an additional Emergency Purchase Order (EPO) to a contractor to proceed with the work. A third consideration was the use of an on-going On-Call rehabilitation contract that included pay items that could be utilized for the work. Initially, the first item that needed to be addressed was identifying the limits of shutdowns to take place, the access points to the distressed pipeline segment, and if dewatering would be required. Plans for an external repair were quickly eliminated due to the proximity of the damaged section to a below-grade crossing of a large thoroughfare, Lawndale Avenue. As records were examined it became clear that the location of the distressed segment was just after an increase in depth for this crossing, and below the driving lanes of the street. Due to the short time frame available, planning, permitting, and utilizing an acceptable traffic control at the location in order to excavate, it was deemed prohibitive to the work, and an internal repair was identified as the primary option. This would require not only isolating the water line and removing pressure, but dewatering the portion of the line where internal access would be needed. With LAN’s previous experience with repairs and internal assessment of the water line, the team had critical knowledge on which valves known to have issues, and manways were a suitable size to facilitate the entry and repair. There were several nearby valves that held water in the past, but only a few manways to be used.

With confined space entry and work in water lines, one critical portion of planning is safety for workers within the water line and air supply to perform the work. Frequently, this is performed with multiple outlets being opened and airflow being pushed through the water line from one side of the dewatered section to the other. During previous condition assessment efforts in 2010, the lower section crossing beneath Lawndale Avenue had been entered and assessed with installation of the AFO system. At that time isolation valves on either side of the crossing were confirmed to operate and an additional valve was installed east of the current segment in need of repair. Additional upgrades at that time increased the size of the manhole installed on the waterline providing larger manholes for getting access into the pipe, since the original water line was installed with access manways too small to safely get materials, airflow, and crew within the water line.

The team evaluated different construction methods, such as a welded repair and various re-lining methods, considering the future loading that will be in place. American Water Works Association (AWWA) Manual M28 includes several different classes of internal lining systems for use with a PCCP pipe. It is common for a Class IV system to be used, or otherwise one that can carry the full internal and external loading as the host pipe continues to degrade. This situation limited the methods to be used to either an internal welded steel liner or carbon fiber repair. The team then made a final decision for repairs that considered the potential repair methods, the contracting methods available, shutdown limits, dewatering limits, access point, and timeframe of when the repair could be made.

At this point LAN and the City of Houston’s Capital Projects and Drinking Water Operations teams began narrowing down the available options to make a final decision. Several factors ended up being key in the final decision with the contracting method being critical. Due to the different options for contracting, the City had the ability to utilize an existing construction contract or select a contractor from a small pre-qualified pool to issue an emergency purchase order for the work. From the available options, it became apparent that the existing on-call contractor did not have the available budget necessary to perform the repair leaving the 72-inch water line contractor or an EPO. Out of the available contractors, there were a few considered for internal welded repairs. This quickly narrowed the options. One contractor, which was already expected to be working downstream from the proposed repair location with the assessment and rehab, included as part of that contract. As the time of the shutdown and repair was getting closer, it became clear that utilizing the 72-inch water line contractor through issuing, a work change directive would provide the flexibility necessary to have a qualified contractor on board to perform the work and flexibility to adjust as needed. Since the contract included a shutdown, assessment, and rehabilitation for other portions of the 60-inch PCCP water line, the team met with the contractor and started to finalize the plans. A work change directive was issued for the additional work required to repair the distressed segment near Wayside and Lawndale. All parties involved agreed to use this existing contract and rehabilitation already specified, installing an internal carbon fiber reinforced polymer (CFRP) liner.

CFRP liners are commonly used as a fully structural liner for distressed PCCP when a few pipe segments are in need of repair. The unit costs can be much higher than replacement, however CFRP often requires the least amount of preparation work and can minimize the shut down duration. CFRP repairs are an iterative process where panels of carbon fiber are saturated with a resin, transported inside of the pipeline, applied to the internal surface of the pipe, and then cured. AWWA Standard C305 provides parameters for this type of repair including design and installation and can be referred to for more details on the installation. For this application, a design was submitted for the weakest design class of the 60-inch PCCP. The additional work was ready to begin once the shutdown occurred.

The shutdown and repair went smoothly for both the North 60 portion included in the 72-inch waterline project and the additional distressed segment at Lawndale and Wayside. This work resulted in the North 60 having an updated assessment and resulted in all segments of pipe with any measured broken prestressing wires to be repaired. The project concluded more than two decades since the previous failure in 2003 and resulted in all segments identified within the line with any level of distress to be rehabilitated and prepared for the future. Though the work took considerable planning, multiple capital improvement projects, emergency repairs, and decades of in-line monitoring, the City has continued to maintain an acceptable level of service in the pipeline with confidence it will continue to provide water services to its more than 2 million residents.

Benjamin McCray PE is a Senior Project Manager, Lockwood, Andrews & Newnam, Inc.

Joseph Wager EIT is a Graduate Engineer, Lockwood, Andrews & Newnam, Inc.